The Ultimate Guide to Acoustic Imaging Cameras

Author: James Osborne Date Posted:3 October 2025

The Ultimate Guide to Acoustic Imaging Cameras: How HIKMICRO Transforms Leak Detection and Electrical Fault Prevention

1. Introduction

Acoustic imaging cameras are changing how industries detect compressed gas leaks, identify electrical partial discharges, and implement predictive maintenance. These tools give maintenance teams the power to “see” sound — capturing high-frequency noise from leaks or faults and visualising it in real time.

At the forefront of this technology is HIKMICRO, whose AI Series acoustic imaging cameras deliver powerful diagnostics, built-in AI leak recognition, and instant ROI tracking.

This guide explores the science, benefits, and industrial applications of acoustic imaging — and why the HIKMICRO AI56, AI56L, and AI76 stand out as market leaders in Australia and beyond.

2. What is an Acoustic Imaging Camera?

An acoustic imaging camera detects ultrasonic frequencies (typically 20–100 kHz) and uses beamforming to locate and visualise the source of sound. These ultrasonic emissions are generated by:

- Compressed air or gas escaping

- Electrical discharge (corona, arcing)

- Mechanical friction from failing bearings

- Vacuum leaks and steam trap failures

The result? A real-time visual heatmap showing where the sound is strongest — overlaid on a video feed of the environment. Think of it as thermal imaging for sound, but more precise for gas and discharge faults.

3. How Acoustic Imaging Works

HIKMICRO’s acoustic cameras feature a dense MEMS microphone array (64 or 136 microphones) that listens across a wide frequency band.

- Microphones detect ultrasonic sound

- Onboard processor triangulates the source (beamforming)

- Sound intensity is rendered as a colour-coded heatmap

- Leak or discharge data (dB, kHz, distance, leak rate) is shown

- Tagged images and video can be saved instantly

Unlike handheld ultrasonic detectors, acoustic cameras give immediate, wide-area coverage with visual context.

4. What Acoustic Cameras Detect

- Mechanical Faults: Bearings, misalignment, motors

- Gas and Air Leaks: As small as 0.0047 L/min

- Partial Discharges: Corona, floating, particle, surface

- Steam Traps: Identify stuck-open/closed traps via ultrasonic signatures

5. HIKMICRO AI Series Overview

| Model | Microphones | Display | Leak Sensitivity | PD Detection | Best Use |

|---|---|---|---|---|---|

| AI56 | 64 MEMS | 4.3" LCD Touch | >0.008 L/min @ 6 bar | Yes | Utilities, general inspections |

| AI56L | 64 MEMS | 4.3" LCD Touch | Same as AI56 | No | Lightweight variant |

| AI76 | 136 MEMS | 4.3" LCD Touch | >0.0047 L/min @ 6 bar | Yes | Industrial-scale inspections |

6. Applications Across Industries

| Industry | Use Case |

|---|---|

| Food & Beverage | Air leak detection on pneumatic lines |

| Utilities & Power | Corona discharge on substations |

| Manufacturing | Compressed air loss, motor bearing faults |

| Mining & Resources | High-pressure air/gas inspections |

| Oil & Gas | Vacuum integrity, pressure leak testing |

| Pharmaceuticals | Cleanroom vacuum and compressed air leaks |

| Facilities Management | HVAC fan motors, ductwork inspection |

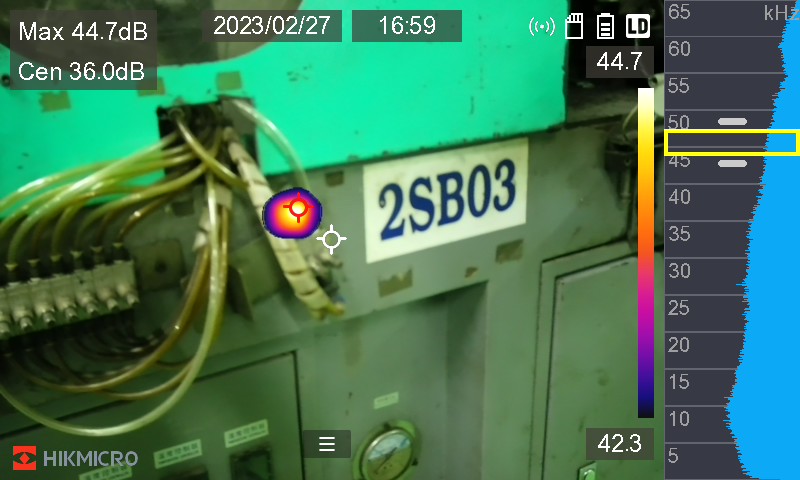

7. Partial Discharge Detection with HIKMICRO

Partial discharges can occur well before failure — and cost millions in downtime or transformer replacement. HIKMICRO AI cameras detect:

- Corona discharge on insulators or connectors

- Floating discharge from loose conductors

- Surface discharge from dirty or degraded insulation

- Particle discharge in enclosed chambers

Example Image:

.jpeg)

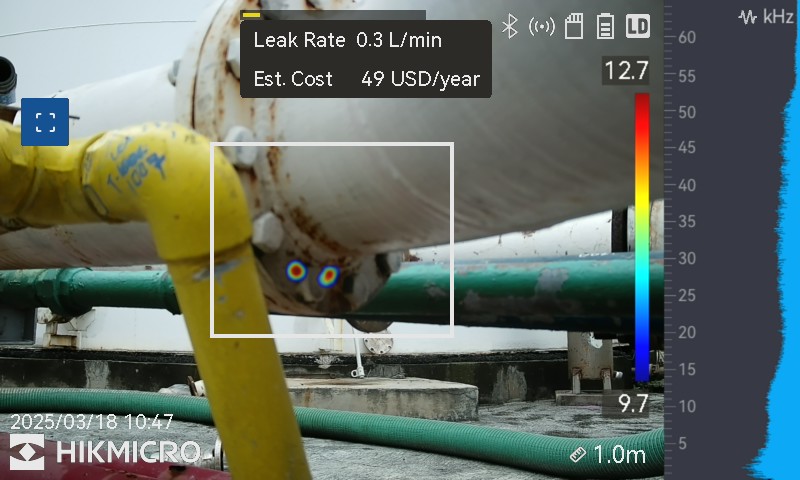

8. Gas and Air Leak Detection with Real ROI

HIKMICRO cameras can detect leaks as small as 0.0047 L/min at 0.5m, and show the cost per year in real time.

Example – AI56 Leak:

Example – AI76 Leak:

9. Built-in AI Leak Classification & Auto ROI

One of the standout features of the AI56 and AI76 is automatic leak detection and classification. The onboard AI will:

- Automatically locate and highlight leak sources

- Classify leaks by confidence level (Low / Medium / High)

- Estimate leak rate in L/min

- Display financial impact in real-time (AUD / EUR / USD)

- Calculate potential carbon emission equivalents (kg CO₂/year)

Example: During a compressed air survey, the AI76 detected six leaks over 80 minutes. Total estimated annual loss: $5,741 AUD.

10. Visualisation and Reporting

HIKMICRO’s intuitive software lets you:

- Capture images and video with audio overlays

- Tag leaks with GPS location

- Add custom notes and fault severity levels

- Export detailed inspection reports with images, values, locations, and estimated costs

This level of documentation is ideal for proving ROI to management, prioritising repairs, and maintaining a clear maintenance audit trail.

11. Comparing Acoustic vs Ultrasonic Tools

| Feature | Ultrasonic Wand | HIKMICRO Acoustic Camera |

|---|---|---|

| Coverage Area | 1–2 m at a time | Wide field of view (up to 120°) |

| User Skill | Requires training | Visual – easy to interpret |

| Quantifies Leak | No | Yes (L/min + cost) |

| Documentation | Manual entry | Auto tagging, exportable reports |

| PD Detection | Unreliable | Yes – with clear signal and image overlay |

12. Distance and Zoom Capabilities

The AI76 excels at long-range inspections. Many faults can be identified at up to:

- 25–30 metres for corona discharge

- 15–20 metres for medium air leaks

It also features an 8× digital zoom and narrow field-of-view mode for isolating specific assets — perfect for substation or rooftop inspections without climbing or shutdowns.

13. AI76 vs AI56 – Which Is Right for You?

| Feature | HIKMICRO AI56 | HIKMICRO AI76 |

|---|---|---|

| Microphones | 64 | 136 |

| Sensitivity | 0.008 L/min | 0.0047 L/min |

| Detection Range | Up to 15m | Up to 30m |

| Weight | 900g | 980g |

| Best For | General inspections | Substations, large factories, offshore |

14. Why Choose HIKMICRO Acoustic Cameras

- Proven performance in leak detection and PD diagnosis

- Built-in AI and ROI calculations

- Excellent price-to-performance ratio

- No subscription required – free software updates

- Local distributor and support through Testrix

15. Available Models and Accessories

Both the AI56 and AI76 come in rugged carry cases with batteries, chargers, USB cables, and reporting software. Optional accessories include:

- Tripods: For hands-free scanning of hard-to-reach assets

- Carrying Harness: Reduces fatigue during long surveys

- Rugged Tablet: For remote viewing and real-time reporting

Conclusion

Whether you're detecting compressed air losses in a factory or tracking partial discharges on a 33kV insulator, the HIKMICRO AI Series cameras deliver clear, actionable data.

Compared to traditional tools, acoustic imaging is faster, safer, and far more intuitive — and thanks to the built-in AI, you’ll know exactly how much each fault is costing you.

Ready to upgrade your inspections? Contact Testrix today for expert advice on choosing the right HIKMICRO model for your facility.