The Ultimate Guide to Using a Class A Power Quality Analyser: Spotlight on the AEMC 8345

Author: James Osborne Date Posted:10 May 2025

Introduction: Why Power Quality Matters More Than Ever

In an era where modern facilities are filled with sensitive electronic equipment and automation systems, the quality of electrical power is a critical factor in ensuring operational reliability, efficiency, and safety. Poor power quality can lead to equipment failure, downtime, increased energy costs, and compliance issues.

Enter the Class A power quality analyser — a sophisticated tool designed to provide high-precision insights into electrical systems. Among the industry’s most trusted models is the AEMC 8345 PowerPad IV, a feature-rich instrument compliant with international standards like IEC 61000-4-30 Class A. This guide will explore what makes the AEMC 8345 a leading choice, how to effectively use it, and why every facility manager, energy auditor, and electrical contractor should consider deploying it.

Table of Contents

.png)

- What is a Class A Power Quality Analyser?

- Key Applications and Use Cases

- Overview of the AEMC 8345 PowerPad IV

- Compliance and Standards: IEC 61000-4-30 Class A Explained

- Step-by-Step: How to Use the AEMC 8345

- Understanding Power Quality Parameters

- Advanced Features of the AEMC 8345

- Real-World Applications and Case Studies

- Integration with Software and Remote Monitoring

- Buying Considerations and ROI Analysis

- Summary and Final Thoughts

1. What is a Class A Power Quality Analyser?

A Class A power quality analyser is a high-accuracy diagnostic instrument used to monitor, measure, and analyse disturbances in electrical systems. Unlike basic models, Class A analysers are certified to meet rigorous international standards that govern data accuracy, resolution, and synchronization.

Key Characteristics:

- High precision voltage and current measurement

- Time synchronization via GPS or NTP

- Real-time event detection

- Compliance reporting (e.g., EN50160, IEEE 519)

- Long-term trending and waveform capture

Class A analysers are indispensable in industrial environments, utility substations, data centres, hospitals, and anywhere power reliability is crucial.

2. Key Applications and Use Cases

.png)

A power quality analyser like the AEMC 8345 is essential in the following scenarios:

a. Power Quality Audits

- Identify voltage sags, swells, harmonics, flicker, and transients.

- Validate power delivery against EN50160 or utility agreements.

b. Energy Efficiency Studies

- Measure energy usage patterns.

- Identify wastage and inefficiencies.

c. Load Profiling

- Monitor usage trends over time.

- Predict peak loads and optimise demand charges.

d. Root Cause Analysis

- Investigate tripped circuit breakers, failed drives, or overheated transformers.

- Determine if power issues stem from internal loads or supply anomalies.

e. Compliance and Reporting

- Validate power quality for compliance with IEC 61000-4-30 standards.

- Generate reports for ISO audits or contractual obligations.

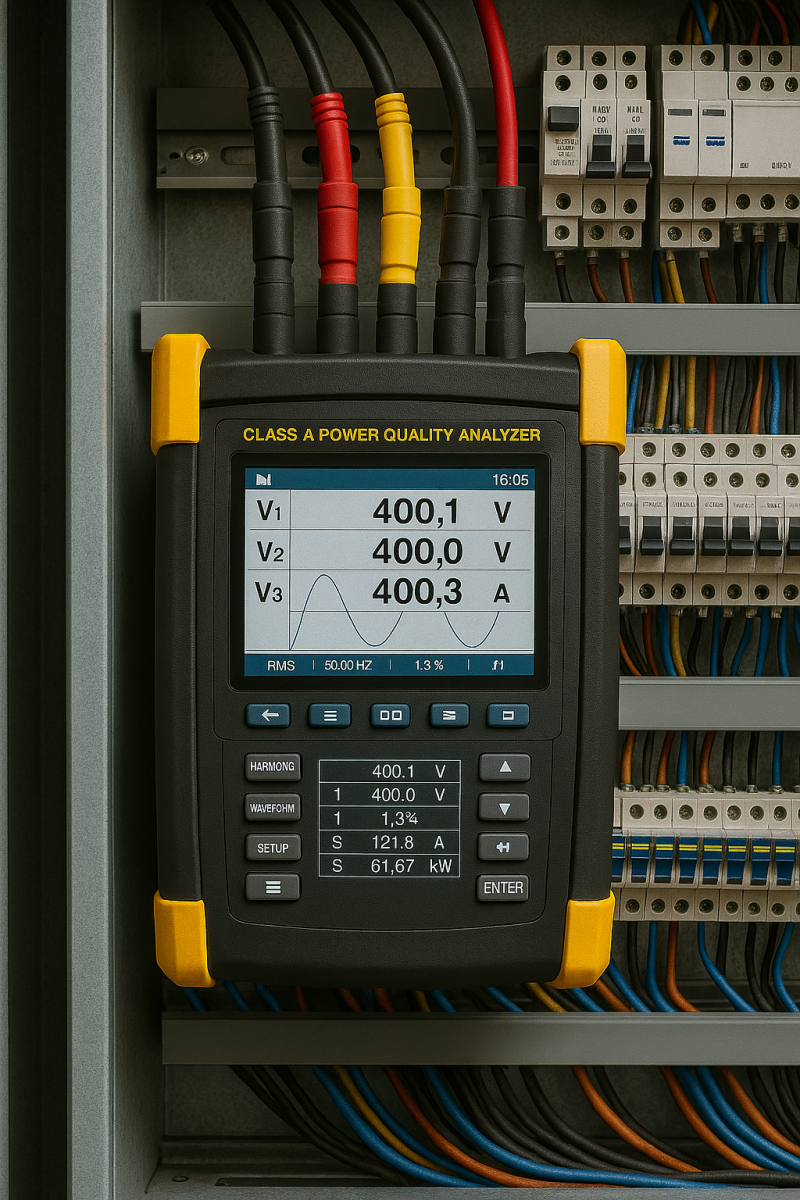

3. Overview of the AEMC 8345 PowerPad IV

The AEMC 8345 PowerPad IV is a 4-channel, Class A certified power quality analyser designed for advanced diagnostics in 3-phase and single-phase electrical systems.

Key Specifications:

- Measurement Channels: 4 voltage & 4 current channels

- Compliance: IEC 61000-4-30 Class A Edition 3

- Voltage Range: 1000Vrms CAT IV

- Current Range: Supports multiple CT options up to 10,000A

- Sampling Rate: 256 samples/cycle

- Recording Memory: 1TB SSD with real-time data streaming

- Display: 7" colour touchscreen

- Connectivity: Ethernet, Wi-Fi, USB, GPS

The AEMC 8345 also supports EN50160 compliance, harmonic spectrum up to the 127th order, and advanced event capture.

4. Compliance and Standards: IEC 61000-4-30 Class A Explained

IEC 61000-4-30 defines the measurement methods and performance criteria for power quality instruments. Class A designation ensures:

- High accuracy and repeatability

- Time-synchronised data acquisition

- Standardised event detection

- Reliable comparisons across multiple instruments

This makes Class A instruments like the AEMC 8345 suitable for contractual dispute resolution, compliance documentation, and network-wide monitoring.

5. Step-by-Step: How to Use the AEMC 8345

a. Installation and Setup

- Mount the unit in a safe, accessible location.

- Connect voltage leads to phases (L1, L2, L3) and neutral.

- Clamp current transformers (CTs) securely on the conductors.

- Ensure all connections are correct and grounded.

b. Configuration

- Use the touchscreen or software to:

- Define circuit type (Wye or Delta)

- Set current sensor type and ratio

- Synchronize time (preferably via GPS)

c. Recording and Logging

- Set logging intervals (1s to 10min)

- Choose parameters to monitor (harmonics, voltage events, energy usage)

- Enable event triggering for sags, swells, and transients

d. Data Retrieval

- Download via USB, Ethernet or Wi-Fi

- Use DataView® software for analysis and reporting

6. Understanding Power Quality Parameters

To fully leverage the AEMC 8345, users must understand what each parameter means and what it reveals:

a. Voltage Sags and Swells

- Indicate over- or under-voltage events.

- Common causes: switching loads, utility faults.

b. Harmonics (THD, individual orders)

- Caused by nonlinear loads like VFDs or UPS systems.

- Lead to overheating and equipment failure.

c. Transients

- Extremely short overvoltage spikes.

- Often result from lightning or switching.

d. Unbalance

- Voltage/current differences between phases.

- Can damage 3-phase motors.

e. Power Factor

- Low power factor means inefficient power usage.

- Leads to higher utility bills.

f. Frequency Stability

- Deviations can damage sensitive electronics.

- Critical in generator applications.

7. Advanced Features of the AEMC 8345

The AEMC 8345 offers several features that differentiate it from standard power quality tools:

- GPS Synchronisation: Accurate time-stamped data across multiple sites.

- Touchscreen Interface: Intuitive navigation for onsite configuration.

- Real-Time Oscilloscope View: View waveform distortions live.

- Trend Mode: Visualise changes in power quality over hours or days.

- FFT Analysis: Deep dive into harmonic content.

- DataView® Integration: Automated reports, graphical analysis, and data overlay.

- Email Alerts: Immediate notification on voltage events or limit violations.

8. Real-World Applications and Case Studies

Case Study 1: Hospital Backup Generator Testing

A Sydney-based hospital used the AEMC 8345 to verify generator transfer quality. Results showed harmonic spikes during transitions, prompting filter installation.

Case Study 2: Manufacturing Plant Energy Audit

In Melbourne, an industrial facility used the 8345 to monitor their 3-phase power for two weeks. The findings revealed a low power factor and load imbalance, leading to corrections that saved over $10,000 annually.

Case Study 3: Utility Substation Compliance

A regional energy provider deployed AEMC 8345 units across 12 substations to document EN50160 compliance. The audit results helped settle a customer dispute and supported infrastructure upgrades.

9. Integration with Software and Remote Monitoring

The AEMC 8345 seamlessly integrates with DataView® software:

Features of DataView®:

- Remote configuration

- Real-time visualisation and data streaming

- Custom report generation (PDF, CSV, XLSX)

- EN50160, IEEE 519, and user-defined compliance templates

- Automated email alerts

Users can also push data to cloud-based SCADA platforms for enterprise-level monitoring.

10. Buying Considerations and ROI Analysis

Why Choose the AEMC 8345?

- Fully Class A compliant for legal-grade diagnostics

- Rugged and versatile for field or panel mount

- Long-term data logging with 1TB storage

- Intuitive software and touchscreen interface

Return on Investment (ROI)

Though more expensive than entry-level models, the ROI is substantial:

- Prevents unscheduled downtime

- Reduces energy waste

- Supports compliance avoidance of penalties

- Enables predictive maintenance

11. Summary and Final Thoughts

The AEMC 8345 stands as a benchmark Class A power quality analyser, offering unparalleled precision, configurability, and usability. For anyone tasked with ensuring electrical system reliability, performing compliance testing, or conducting energy audits, it’s an essential tool.

From harmonics and flicker to transient spikes and voltage events, the AEMC 8345 empowers you to understand, optimise, and protect your electrical infrastructure.

Whether you're an industrial engineer, facility manager, electrical consultant, or utility technician, the AEMC 8345 provides the insight you need — with the accuracy you can trust.

Need more information?

Looking to enhance your power quality monitoring capabilities?

Explore the AEMC 8345 on Testrix Systems — Australia's trusted supplier of industrial diagnostic tools.

Contact us for expert guidance, custom quotes, or on-site demonstrations.